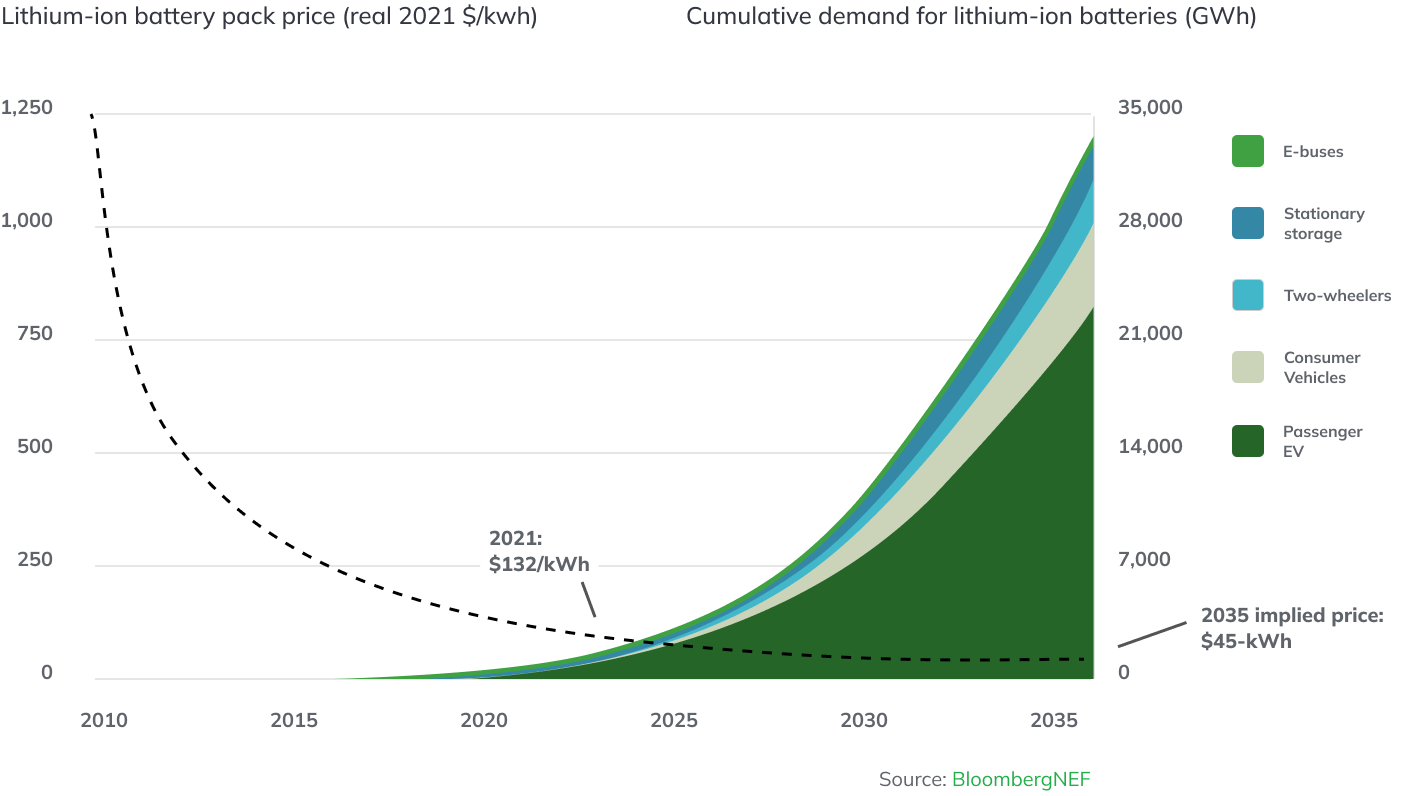

GLOBAL LITHIUM-ION

BATTERY DEMAND, GWh

-

E-buses

-

Stationary storage

-

Electric two-wheelers

-

Commercial EVs

-

Consumer electronics

-

Passenger EVs