THE NEED FOR RELIABILITY

Cutting-edge 5G electronic devices operate at faster speeds and higher frequencies by incorporating critical, high-reliability antenna components that operate with minimal delay – referred to as low latency. Flexible Printed Circuit Boards (PCBs) are the foundation for these devices..

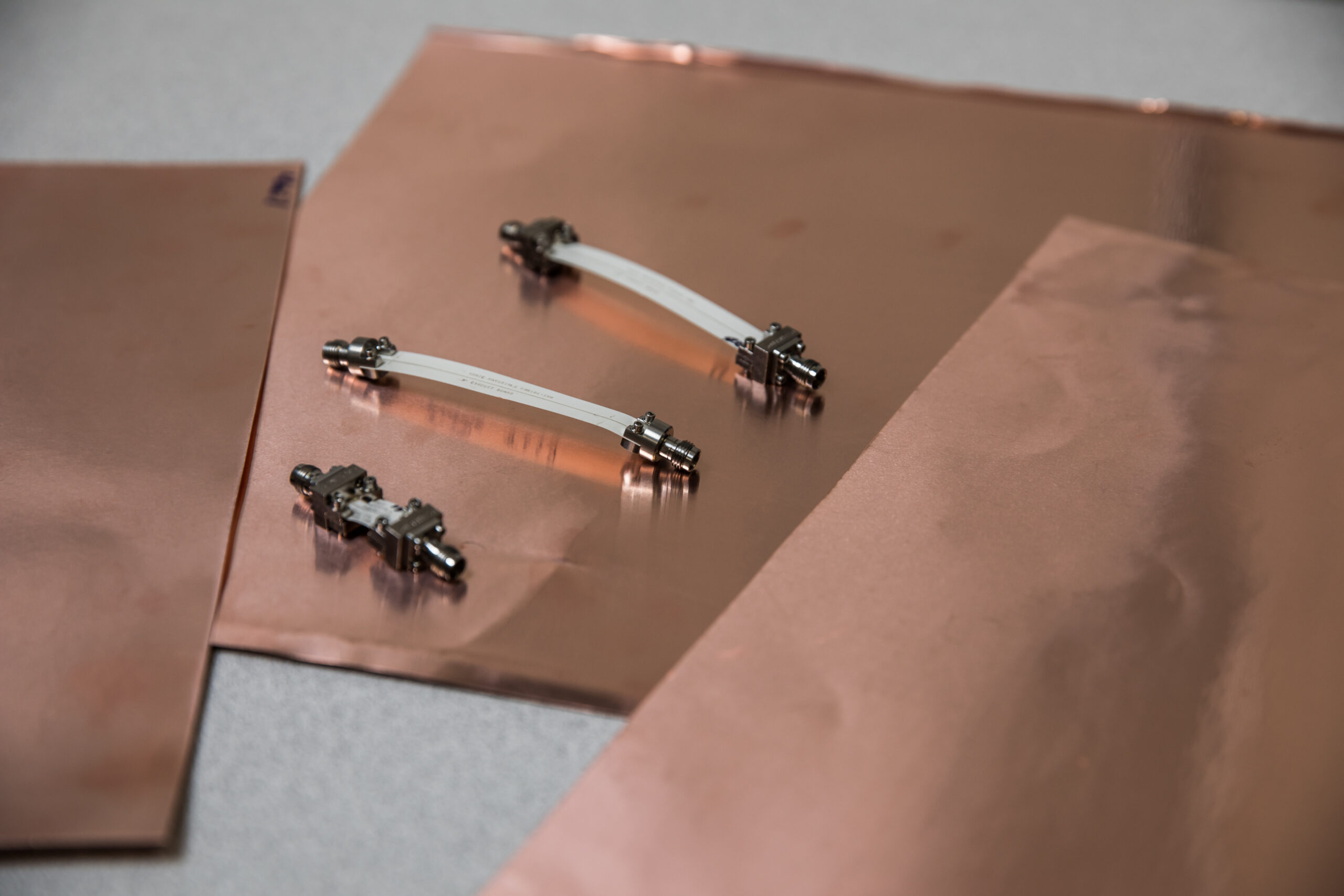

Copper Clad Laminates (CCLs) are the core substrate material in PCBs. These CCLs are made up of a polymer-based dielectric layer with unique electrical and signal properties sandwiched between copper foils. Today’s materials suffer from limited moisture resistance and temperature stability, leading to performance degradation especially at high frequencies. New, specialized materials are needed meet application demands.

Liquid crystal polymers (LCPs) provide a novel and exceptional alternative, due to thermal stability, high moisture resistance, and excellent electrical properties – low dielectric constant and dielectric loss.

TAILORED LCP RESINS IMPROVE

PERFORMANCE

Our polymer expertise enables us to customize solutions to meet very specific technical, and often challenging, requirements.

Not only do our LCPs meet the stringent requirement for 5G applications, but our formulations also deliver greater adhesion, which enables the use of advanced, smoother copper foils such as rolled-annealed (RA) copper. This results in LCP laminates that generate circuits with lower insertion loss and improved signal performance particularly at high frequencies.

Until the development of this LCP family, LCP film technology experienced issues that made it less than ideal as a solution. Ionic has cracked the code on performance, adhesion and manufacturing issues that allows us to meet next-generation requirements.

Process Innovation

5G Market Needs Higher Performance Solutions

Exceptional adhesion enables extremely smooth copper, such as RA copper

RA copper leads to lower insertion loss and improved signal performance, critical at high frequencies

High quality interface promotes lower insertion loss and higher performance