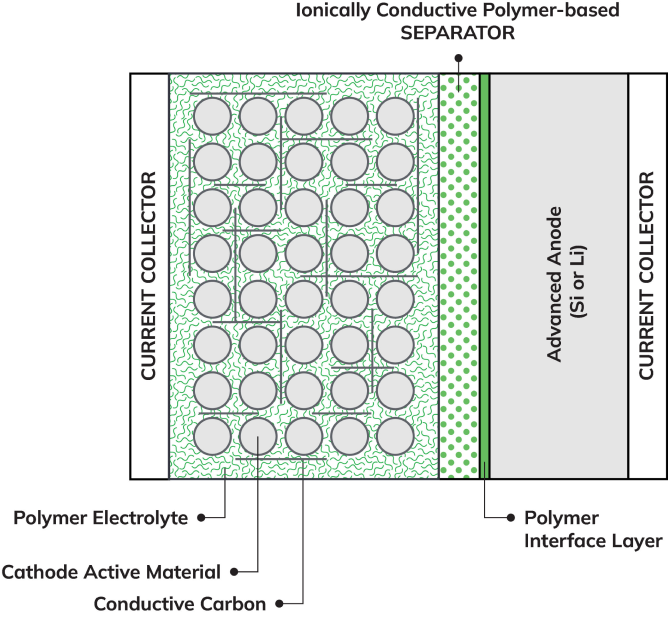

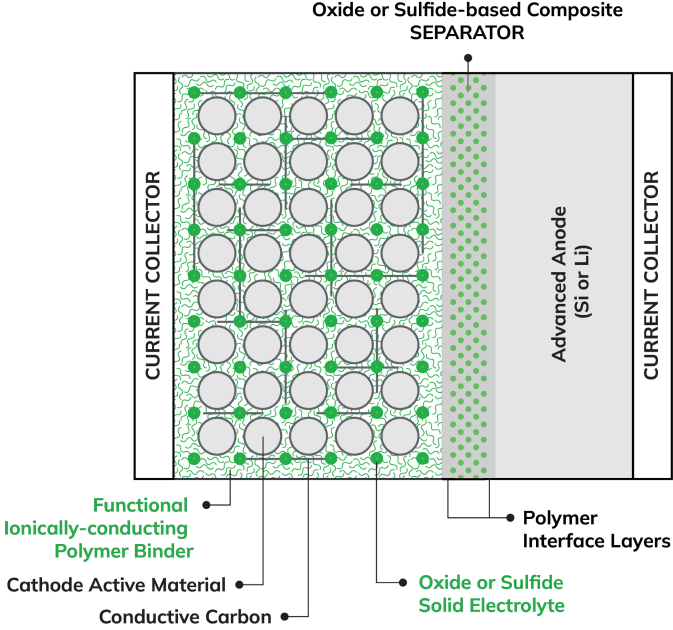

High voltage stable polymers enable new cathode materials

Compositionally distinct catholytes/anolytes decouple single-chemistry electrolyte problem

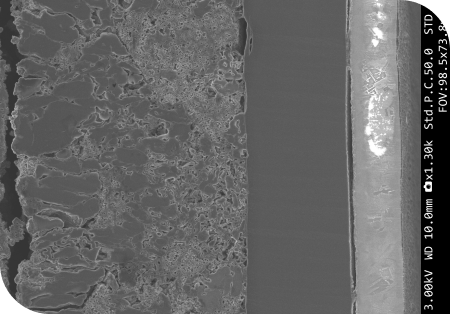

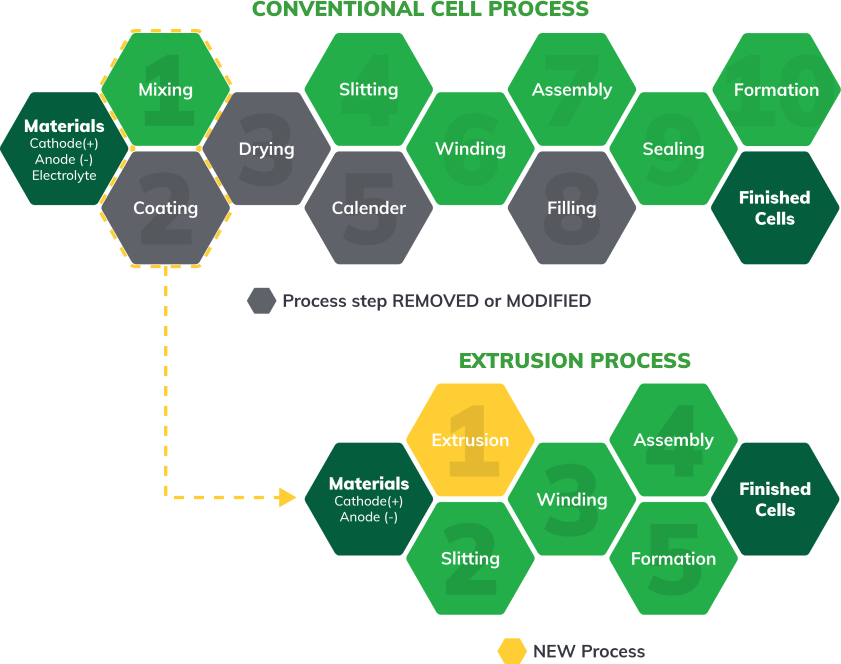

Sulfide-based materials are the leading technology for advanced solid-state designs. However, they can be plagued by performance issues. Specifically, interfacial compatibility and resistance can play key roles in limiting performance. Polymers can provide a great enabling function for commercialization of new solid-state cell designs by improving interfacial contact and resistance control during operation. This can change the game for solid-state battery manufacturers, enabling higher levels of performance, stability, and scalability from their cells.

IONIC POLYMERS FOR SOLID STATE CELLS

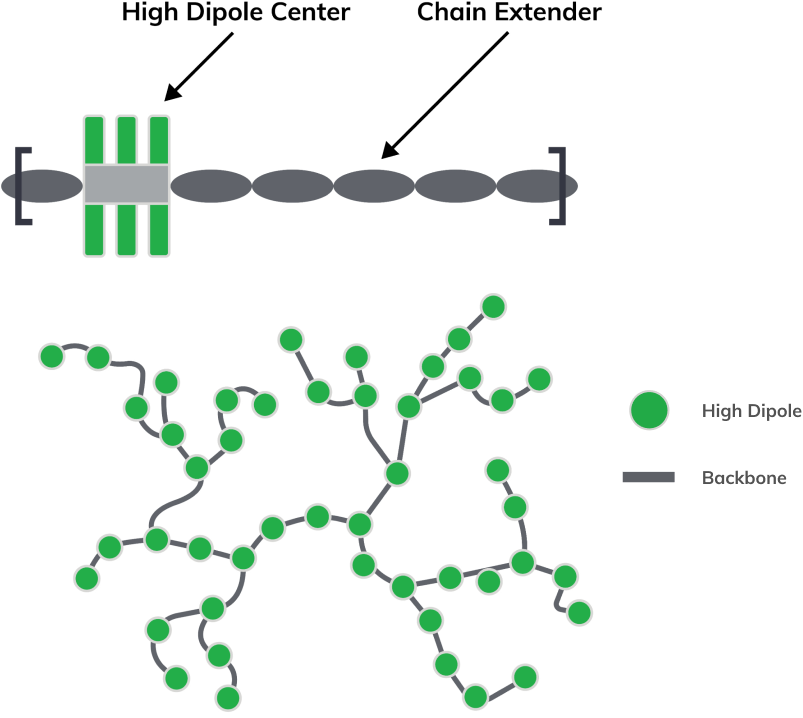

Ionic Materials if focused on developing a unique class of High Dielectric Polymers (HDP) designed to enhance functional movement of ions in advanced lithium-ion cells, including Solid-State.

- High Dielectric Permittivity

– high polarity side groups - Low Glass Transition Temp (Tg)

– fast segmental relaxation - High Oxidative Stability

– thermodynamic stability in the voltage environment of lithium-ion cells