CONNECTING THE FUTURE OF HIGH-SPEED, HIGH-FREQUENCY DEVICES

At Ionic, our goal is to connect people through material innovation designed for the next generation of communication devices. The move to 5G devices requires advanced materials like Liquid Crystal Polymers to meet rigorous performance specifications.

MarketsNEXT-GENERATION INNOVATIVE POLYMERS

& SCALABLE PROCESSES

At Ionic, enabling performance at higher, 5G frequencies means the development of novel materials that meet demanding requirements and advanced manufacturing processes for high volume production capability.

Polymers

Our experts have a deep understanding of Liquid Crystal Polymers and developed formulations to deliver specific properties. IM formulated LCP resin technology with improved adhesion, superior to incumbent LCP film, enabling LCP laminates to use much smoother copper foils, such as rolled annealed (RA) copper foil. This lamination construction delivers lower insertion loss and improves signal performance for high frequency, antenna applications.

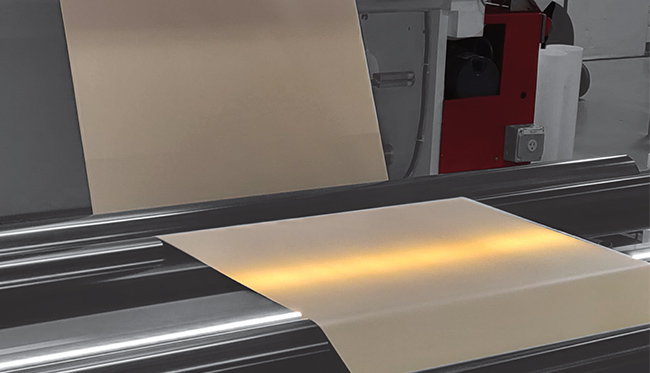

Process

Moreover, and equally critical, is the process technology developed to produce balanced, isotropic LCP film and manufacture in high volumes for LCP copper clad laminates (CCLs) and flexible circuit applications.

Ionic’s team has pioneered manufacturing methods to achieve industry-leading performance for LCP film with high adhesion, leading to exceptionally low insertion loss for high-frequency circuit applications. The highest performing 5G devices are achieved through innovative materials and processes.